TYPEFACE WAR: CHESSBOARD

DESIGNER / SHERYN BALDAS / 2024

BUILT / FREELANCE WORK

Blending the principles of Visual Communication Design (VCD) in the use of typefaces, manufactured using in the Industrial Design (ID) method of 3D printing.

OBJECTIVE

BUILT is a design market hosted by the University of Alberts Student Design Association (SDA), bringing in current undergraduates, alumni and MacEwan design students to sell their work. The objective is to create a product to anticipate and bridge user requirements, aesthetic and function with the cost and presentation in the market.

MANUFACTURING

To create a unique chessboard that unifies the visual communication design principles of typefaces and typography with the industrial design manufacturing method of CAD modelling and 3D printing. This chessboard serves as a love letter to my ever-evolving understanding of design, and marks a milestone in producing a product for the market. The goal is to create one chessboard for display and five to be sold. However, as the time constraint consisted of one month to produce, this goal eventually became unachievable, opting instead to sell two for the market. This encompassed the CAD modelling and concept refinement, this process overtook the time to 3D print. A sample time being thirteen hours to print one-fourth of one chess board, not accounting for the pieces, packaging time and booklet.

PRICING

Upon leveraging the market pricing and cost analysis of raw materials, it became apparent that one chess set amounted to become much more expensive than initially projected. I began reaching out to my peers and professors for advice, and concluded that the range of $250-$350 became my target for compensating my labour and profit.

OBJECTIVE

BUILT is a design market hosted by the University of Alberts Student Design Association (SDA), bringing in current undergraduates, alumni and MacEwan design students to sell their work. The objective is to create a product to anticipate and bridge user requirements, aesthetic and function with the cost and presentation in the market.

MANUFACTURING

To create a unique chessboard that unifies the visual communication design principles of typefaces and typography with the industrial design manufacturing method of CAD modelling and 3D printing. This chessboard serves as a love letter to my ever-evolving understanding of design, and marks a milestone in producing a product for the market. The goal is to create one chessboard for display and five to be sold. However, as the time constraint consisted of one month to produce, this goal eventually became unachievable, opting instead to sell two for the market. This encompassed the CAD modelling and concept refinement, this process overtook the time to 3D print. A sample time being thirteen hours to print one-fourth of one chess board, not accounting for the pieces, packaging time and booklet.

PRICING

Upon leveraging the market pricing and cost analysis of raw materials, it became apparent that one chess set amounted to become much more expensive than initially projected. I began reaching out to my peers and professors for advice, and concluded that the range of $250-$350 became my target for compensating my labour and profit.

OUTCOME

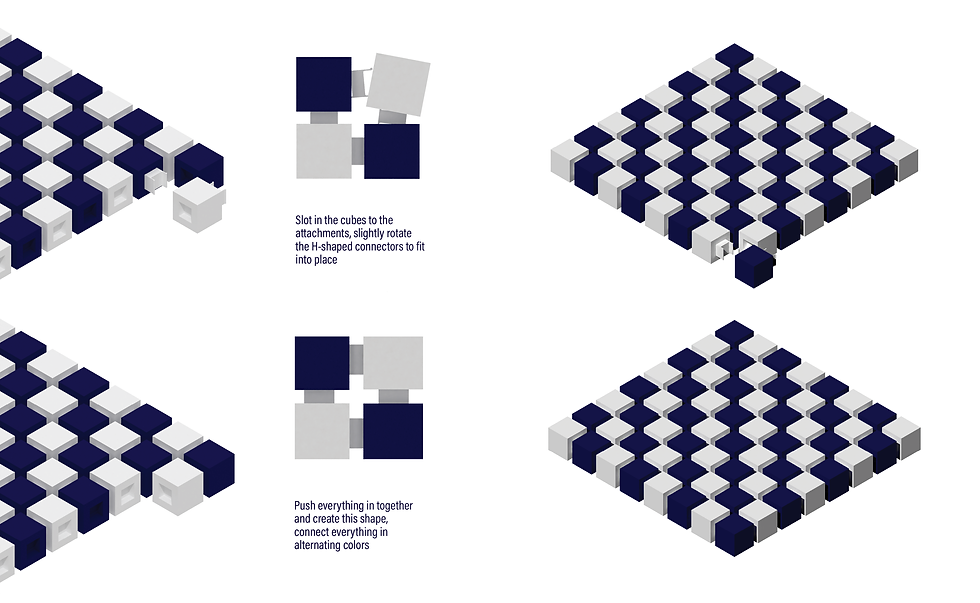

The typeface war chessboard is a blend of my skills founded in Visual Communication and Industrial design, offering a modular and atypical design and concept of the board. The chessboard is completely modular yet stable. Held together with 3D printed boxed forms and H-shaped clasps, stabilized through the tension of closely calculated tolerance. The manual guide shows how the chess board can be assembled and to explore the history of both 3D printing and typefaces. Overall the product, the looks and interactivity, was a highlight. Alongside the planning and tolerance testing serving to elevate the interaction.

LEARNED SKILLS

Anticipation became a skills cultivated throughout this project, in the target audience and user needs, cost analysis (which was one of my biggest struggle) alongside the 3D printing time. I have my own personal 3D printer thoroughly used in the project (the Bambu Lab P1S with the AMS). However, due to the scale and size I was printing in, alongside the modular parts, the printing time totalled to around four days to print one chessboard, twelve hours to print sixteen of the boxes. This accounts print quality and infill to produce the best and highest quality. To help produce the desired amount (one display + two sold), I employed fellow designers with the BambuLab 3D printer for the remaining elements, such as the connector clasps and typeface chess pieces. The most eye-opening process is the cost, bridging the material, time and labour of the chessboard amounted it to cost $300 in order to make profit. Overall the skills of anticipation, time management, project management (through employing three amazing designers for the project) and cost analysis were only some, but the main takeaways from this project. I was able to sell the chessboard, so that is a win for me...

CREDITED DESIGNERS

Michael Torres

Thomas Gibbons

Joy Jia